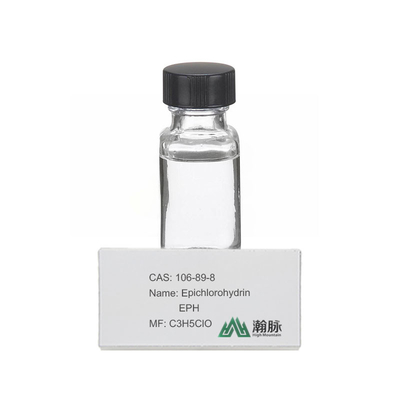

3-Chloropropylene oxide for epoxy resin production Pharmaceutical Intermediates

Basic Information

Model Number: HMHT0008-12

Appearance Liquid

Exposure Limit TLV-TWA (skin) 8 mg/m3 (2 ppm) (ACGIH); STEL (15 min) 19 mg/m3 (5 ppm) (NIOSH)

Storage Condition Store below+30 ° C

Molecular Formula C3H5ClO

Vapor Presure 13.8 mm Hg (21.1 ° C)

Reflective Index n20/D 1.438 (lit.)

The production process of epoxy chloropropane involves several steps. It is primarily manufactured through the chlorination of propylene followed by epoxidation. The process begins with the reaction of propylene with chlorine to form allyl chloride, which is then further reacted with hypochlorous acid to produce epichlorohydrin. This compound is then purified and processed to obtain the final product.

Glycerol Epichlorohydrin

(chloromethyl)oxirane

3-Chloropropene-1,2-oxide

EPICHLOROHYDRINE

(chloromethyl)ethyleneoxide

3-Chloropropylene Oxide

Product Parameters

We can provide 25kg bagor as per customers' requirements.

1.It is mainly used in the production of epoxy resin, synthetic glycerol, chloroalcohol rubber, nitroglycerine explosive, glass

chloroprene rubber.

Company Profile

![]()

Wuxi High Mountain Hi-tech Development Co., Ltd is a professional industrial company specializing in the production of specialty chemicals, technology research & development, and import & export. The company is dedicated to the production, trade, and research of various chemical products.

Since its establishment, the company has focused on establishing an international marketing network and optimizing supply chain management. It has built long-term strategic partnerships with numerous large enterprises both domestically and internationally. Leveraging its extensive business channels and professional experience, the company adeptly provides products of stable but differentiated quality, along with flexible, highly efficient, and considerate service at competitive pricing to meet the needs of its partners.

The company treats its customers as partners with sincerity, specialization, and satisfaction as its guiding principles. Supported by a dedicated technical team with extensive knowledge and 20 years of experience in chemicals and international trade, the company has rich expertise in product quality control, technical solutions, chemical logistics organization, packaging optimization, port operation, and more. This contributes to its superior cost control management and ensures it maintains a significant competitive advantage over others.

Following the principle of sharing preferential costs and joint development, the company has cultivated a strong community with its customers at home and abroad over the years. Its objective is to foster a trusting, cooperative, win-win, and value-added sustainable partnership to grow together with its partners.