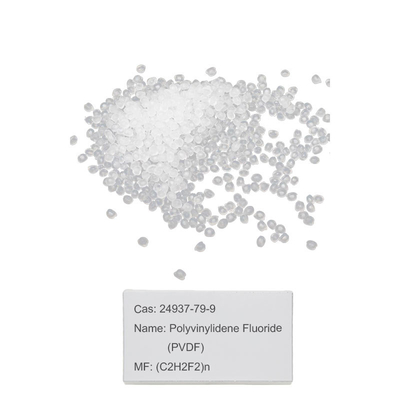

Polyvinylidene Fluoride Resin PVDF White Powder Fluorine-Containing Resin Lithium Battery Material

Model Number : HMHT0171

Other Names : PVF2;PVDF;MW~180000;MW~534000;MW~530000;PVDF/PVF2;P(VDF-co-TrFE);Polyvinylidene fluor;poly(vinylene fluoride);POLY(VINYLIDENE FLUORIDE)

Molecular Formula : -(C2H2F2)n-

CAS NO. : 24937-79-9

EINECS NO. : 607-458-6

Product Parameters

|

Melting poin

|

166-170°C

|

|

Solubility

|

some polar solvents such as organic esters and amines: soluble

|

|

Density

|

1.78 g/mL at 25 °C

|

|

Vapor pressure

|

15 mm Hg ( 32 °C)

|

|

Inchi

|

n20/D 1.42

|

Physical and chemical properties

Poly(vinylidene fluoride), English abbreviation PVDF, mainly refers to vinylidene fluoride homopolymer or copolymer of vinylidene fluoride and other small amount of fluorine-containing vinyl monomer, which has the characteristics of fluorine resin and general resin , In addition to good chemical resistance, high temperature resistance, oxidation resistance, weather resistance, radiation resistance, it also has special properties such as piezoelectricity, dielectricity, and pyroelectricity. The second largest product, with a global annual production capacity of more than 53,000 tons.

In the chemical structure, fluorine-carbon bonds are used, and this structure with short bond properties forms the most stable and firm bond with hydrogen ions. Therefore, fluorocarbon coatings have specific physical and chemical properties, not only strong wear resistance and impact resistance, but also high fading resistance and UV resistance in extremely harsh and harsh environments.

Packaging Types

25kg/ drum or as per customers ' requirements .

![]()

Transport/Storage Information

PVDF should be stored in a clean and dry environment at 5-30°C to avoid the mixing of impurities such as dust and moisture. Transport as non-dangerous goods, avoid heat, moisture or severe vibration during transportation.

Applications

PVDF applications are mainly concentrated in the three major fields of petrochemical, electrical and electronic and fluorocarbon coatings. Due to its good chemical resistance, processability, fatigue resistance and creep resistance, PVDF is the whole or lining pump and valve of petrochemical equipment fluid processing system. One of the best materials for , pipes, pipe fittings, storage tanks and heat exchangers. PVDF has good chemical stability and electrical insulation properties, so that the produced equipment can meet the requirements of TOCS and flame retardant, and is widely used in the storage and transportation of high-purity chemicals in the semiconductor industry. Separator, etc., are used in lithium secondary batteries. At present, this application has become one of the fastest growing markets for PVDF demand. PVDF is one of the most important raw materials for fluorocarbon coatings. The fluorocarbon coatings prepared from it have developed into the sixth generation. Because PVDF resin has super weather resistance, it can be used outdoors for a long time without maintenance. Widely used in power stations, airports, highways, high-rise buildings, etc. In addition, PVDF resin can also be modified by blending with other resins. For example, PVDF and ABS resin can be blended to obtain composite materials, which have been widely used in construction, automobile decoration, and home appliance shells.

Company Profile

![]()

Wuxi High Mountain Hi-tech Development Co., Ltd is a professional industrial company engaged in special chemical production, technology research & development, and import & export. The company focuses on the production, trade, and research & development of various chemical products.

Since establishment, the company has been concentrating on constructing an international marketing network and optimizing supply chain management, where we have established a long-term strategic cooperation relationship with numerous large enterprises at home and abroad. Relying on our wide business channels and professional experience, we are more skillfully providing products of stable but differentiated quality, along with flexible, highly efficient & considerate service to satisfy our partner at more competitive pricing.

Efficiently treating our customers as partners with sincerity, specialization and satisfaction is our managerial principle. Attributed to the backup of a dedicated technical team, filled with wide and profound knowledge and practice in chemicals and world trade for 20 years, the company owns rich experience in product quality control, technical solution, chemical logistics organization, packaging optimization, port operation, etc., which accounts for its first-class cost control management and ensures to maintain the overwhelming competitive advantage over others. In line with the principle of sharing the preferential cost and joint development, the company has formed an interesting community for years with its customers at home and abroad. Sincerely to build up a pleasant mutual trust, cooperative, win-win, and value-added sustainable partnership is what we are achieving to grow together with you!

![]()

FAQ

A: What about product quality assurance policy?

Q: We accept pre-shipment test by SGS or any other third party agents.

A: How long have you been engaged in Chemicals?

Q: We have been engaged in Chemical exports since the year 1992.

A: What are your payment terms?

Q: We accept T/T,L/C,D/P and CAD, etc.

A: What is the delivery time?

Q: Usually about 7-15 days, depending on the required quantity and product.

A: What certifications do you have?

Q: ISO 9001, HALAL, KKDIK, REACH, etc.