Model Number: HMHT0033-18Melting point 64-68°C (lit.)

Density 1.8g/cm3(20℃)

Vapor pressure 2.68hPa(20°C)

Storage conditions Storebelow+30°C.

Solubility alcohol:sligChemicalbookhtly soluble(lit.)

PH value 9.5-10.5 (100g/l, H2O, 20℃)

CAS database 6035-47-8

Technical Specifications

| EINECS | 205-739-4 |

| CAS | 6035-47-8 |

| Solubility | easily soluble in water, insoluble in absolute ethanol, benzene. |

| Features | It has strong reducibility at high temperature. Has fading properties. |

| Temperature resistance | It decomposes at high temperature to produce toxic gases such as formaldehyde and hydrogen sulfide. |

| Acid resistance | it decomposes when it encounters dilute acid, and its solution is neutral. |

| Melting point | 63~64 ℃. |

| Surface density | 1.80~1.85 g/cm3 |

Packaging Types

25kg bag/50kg iron drum

Customers' requirement

Applications

![]()

![]()

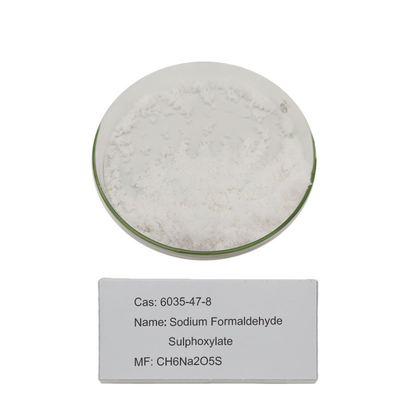

Physical and chemical properties

This product is white crystal. soluble in water. Insoluble in absolute ethanol, benzene. It has strong reducibility at high temperature. Has fading properties. Decomposition at high temperature produces toxic gases such as formaldehyde and hydrogen sulfide. In case of dilute acid, it decomposes, and its solution is neutral. Anhydrous melting point 63 ~ 64 ℃. Surface density 1.80 ~ 1.85 g/cm3.

Product Usage

This product is used in the printing and dyeing industry as a whitening agent, reducing agent, bleaching agent and in the production of indigo dyes and vat dyes. It can also be used in the polymerization of synthetic rubber, sugar and vinyl compounds.

Production method

Add 286 kg of zinc powder and 500 kg of water into the beating tank, and after pulping, add it to the shell-and-tube reactor, and absorb about 550 kg of SO2 to obtain zinc hydrosulfite (the reaction temperature is maintained at 40-45 °C, and the end point is pH value is 3 to 3.5).

In addition, the formaldehyde of 698 kg 40% is added in the reactor, the above-mentioned zinc hydrosulfite aqueous solution is added dropwise under stirring, and gradually heat up, when the temperature rises to 95~100 ℃, add a total of 257 kg of zinc powder in batches, react under the insulation For several hours, the end point is less than 1% unreacted substance. The precipitate was left to stand, and the precipitate was transferred to a displacement kettle. After washing with clean water, 755 kg of 42% sodium hydroxide solution was added under stirring. The reaction was carried out at 65°C until the free base content reached 0.3% to 0.5%. The reactants were filtered to remove impurities, and the filtrate was clarified for 48 h and concentrated in vacuo. Cool to crystallize and pulverize to get the finished product.

![]()

Wuxi High Mountain Hi-tech Development Co., Ltd is a professional industrial company engaged in special

chemical production, technology research & development, and import & export. The company focuses on the

production, trade, and research & development of various chemical products.

Since its establishment, the company has been concentrating on constructing an international marketing

network and optimizing supply chain management, where we have established a long-term strategic

cooperation relationship with numerous large enterprises at home and abroad.

Relying on our wide business channels and professional experience, we are more skillfully

providing products of stable but differentiated quality, along with flexible, highly efficient & considerate

service to satisfy our partner at more competitive pricing.

In line with the principle of sharing the preferential cost and joint development, the company has formed

an interesting community for years with its customers at home and abroad. Sincerely to build up a pleasant

mutual trust, cooperative, win-win, and value-added sustainable partnership is what we are achieving to grow

together with you!