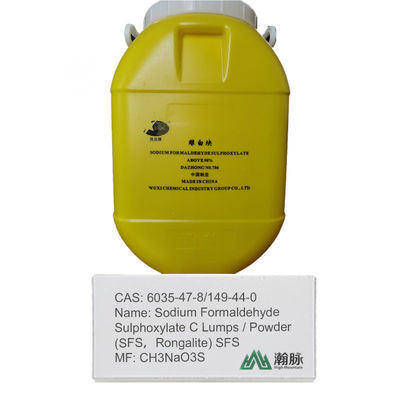

Industrial Rongalite & SFS Supplier Sodium Formaldehyde Sulphoxylate CAS 149-44-0/6035-47-8 Textile & Leather Processing Agent

Sodium Formaldehyde Sulfoxylate, or SFS, is widely used across multiple industries as a reliable reducing agent. Its stable properties and effective performance make it a trusted choice in textile processing, polymer manufacturing, and color stripping applications. Below are several real-world case studies that highlight how SFS delivers value in practical settings.

A textile dyeing and printing factory in South Asia integrated SFS into their discharge printing line. The goal was to achieve clear white patterns on deep-colored cotton fabrics. By using a 10 percent SFS solution in combination with a suitable thickener and dye system, the factory achieved sharp, consistent patterns with minimal fabric damage. Compared to their previous reducing agent, SFS provided better reproducibility and reduced odor emissions during production.

A denim manufacturer in Central Europe adopted SFS to replace sodium hydrosulfite in their vat dyeing process. The switch was driven by environmental concerns and the need for improved bath stability. SFS demonstrated excellent reducing strength, maintained dye solubility throughout the process, and simplified wastewater treatment due to its cleaner breakdown products. The company also reported improved worker safety due to SFS’s lower toxicity and easier handling.

A garment recycling facility in East Asia used SFS in the reprocessing of incorrectly dyed fabric lots. By applying a warm aqueous solution of SFS and a surfactant system, the facility successfully removed residual dyes without degrading fabric quality. This allowed for cost-effective reuse of the materials and supported the company's sustainability goals by reducing fabric waste.

A resin manufacturer in Southeast Asia implemented SFS as a polymerization inhibitor in their acrylic monomer storage system. Prior to this, the company experienced frequent issues with unwanted pre-polymerization during transport and storage. With controlled dosing of SFS, the stability of monomers was significantly improved, leading to fewer production delays and reduced raw material losses.

A paper mill in North America incorporated SFS in their recycled paper bleaching process. The compound was used to decolorize ink residues and brighten pulp before final sheet formation. SFS enabled effective bleaching without the use of chlorine-based agents, resulting in a safer and more environmentally friendly process that met regulatory discharge standards.

Across all these industries, the common advantages of SFS included ease of solubility, consistent reducing performance, low environmental impact, and enhanced safety for operators. These case studies demonstrate the versatility and reliability of SFS as a practical solution to industrial challenges.

Sodium Formaldehyde Sulfoxylate continues to be a dependable choice for manufacturers aiming to improve process efficiency, product quality, and environmental compliance. Its wide range of applications confirms its status as an industry-standard reducing agent.

Wuxi High Mountain Hi-tech Development Co., Ltd is a professional industrial company engaged in special chemical production, technology research & development, and import & export. The company focuses on the production, trade, and research & development of various chemical products.

Since establishment, the company has been concentrating on constructing an international marketing network and optimizing supply chain management, where we have established a long-term strategic cooperation relationship with numerous large enterprises at home and abroad. Relying on our wide business channels and professional experience, we are more skillfully providing products of stable but differentiated quality, along with flexible, highly efficient & considerate service to satisfy our partner at more competitive pricing.

Efficiently treating our customers as partners with sincerity, specialization and satisfaction is our managerial principle. Attributed to the backup of a dedicated technical team, filled with wide and profound knowledge and practice in chemicals and world trade for 20 years, the company owns rich experience in product quality control, technical solution, chemical logistics organization, packaging optimization, port operation, etc., which accounts for its first-class cost control management and ensures to maintain the overwhelming competitive advantage over others. In line with the principle of sharing the preferential cost and joint development, the company has formed an interesting community for years with its customers at home and abroad. Sincerely to build up a pleasant mutual trust, cooperative, win-win, and value-added sustainable partnership is what we are achieving to grow together with you!

![]()

FAQ

A: What about product quality assurance policy?

Q: We accept pre-shipment test by SGS or any other third party agents.

A: How long have you been engaged in Chemicals?

Q: We have been engaged in Chemical exports since the year 1992.

A: What are your payment terms?

Q: We accept T/T,L/C,D/P and CAD, etc.

A: What is the delivery time?

Q: Usually about 7-15 days, depending on the required quantity and product.

A: What certifications do you have?

Q: ISO 9001, HALAL, KKDIK, REACH, etc.