Organic Peroxide Initiators, also known as DCBP, are a type of chemical compound commonly used in the production of plastics, rubbers, and other polymer-based materials. These initiators are highly reactive and can act as powerful oxidizing agents, making them ideal for initiating polymerization reactions.

One of the key properties of Organic Peroxide Initiators is their high boiling point of 495.27°C. This allows them to remain stable and not decompose at high temperatures, making them suitable for use in various industrial processes.

The Einecs No of Organic Peroxide Initiators is 205-094-9, which is a unique identification number assigned by the European Chemicals Agency (ECHA) to substances that are registered under the European Union's chemical regulatory framework, REACH (Registration, Evaluation, Authorization and Restriction of Chemicals).

With a density of 1,26 G/cm3, Organic Peroxide Initiators are relatively dense and can be easily dissolved in solvents or toluene. This allows for easy handling and mixing with other chemicals during the production process.

The flash point of Organic Peroxide Initiators is 194.1°C, which is the lowest temperature at which the vapors from the compound can ignite in air. This high flash point makes them less volatile and safer to handle compared to other types of initiators.

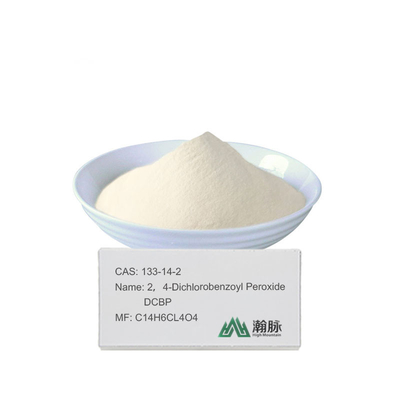

The Cas No of Organic Peroxide Initiators is 133-14-2, which is a unique identification number assigned by the Chemical Abstracts Service (CAS) to substances that have been assigned a CAS registry number. This number serves as a universal identifier for chemical substances.

Organic Peroxide Initiators, with a molecular weight of 380.01, are available in various forms and concentrations, such as powder, liquid, and paste. They are commonly used in the production of polymers such as polystyrene, polyethylene, and PVC, and can also be used as curing agents for resins and adhesives.

In summary, Organic Peroxide Initiators are a vital component in the production of polymer-based materials and offer high stability, reactivity, and safety. With their unique properties and applications, they play a crucial role in various industries and continue to be a popular choice for polymerization processes.

| Property | Value |

|---|---|

| Product Name | Organic Peroxide Initiators |

| Chemical Name | 2,4-Dichlorobenzoyl peroxide |

| Molecular Formula | C14H6Cl4O4 |

| CAS No | 133-14-2 |

| Einecs No | 205-094-9 |

| Molecular Weight | 380.01 |

| Flash Point | 194.1°C |

| Water Solubility | 29.93μg/L at 25℃ |

| Refractive Index | 1.5282 (estimate) |

| Boiling Point | 495.27°C (rough Estimate) |

| Proportion | 1.26 |

| Purity | Customizable |

Brand Name: HMHT

Model Number: HMHT0087

Place of Origin: China

Molecular Formula: C14H6Cl4O4

Flash Point: 194.1°C

Boiling Point: 495.27°C (rough Estimate)

Proportion: 1.26

Melt Point: 55°C (dec.)

Organic Peroxide Initiators, also known as polymerization initiators, are essential compounds used in the production of various polymers, resins, and plastics. These initiators help to kick-start the polymerization process, allowing for the formation of strong and durable materials.

The HMHT Organic Peroxide Initiators are a high-quality product designed and manufactured in China. They are made from the compound BIS(2,4-DICHLOROBENZOYL) PEROXIDE, also known as 2,4-DICHLOROBENZOYL PEROXIDE, with the CAS number 133-14-2. This organic peroxide is a white crystalline solid with a molecular formula of C14H6Cl4O4. It has a flash point of 194.1°C, boiling point of 495.27°C (rough estimate), and a proportion of 1.26. It also has a melt point of 55°C (dec.), making it a versatile and efficient initiator for various polymerization processes.

The HMHT Organic Peroxide Initiators are widely used in the production of plastics, resins, and rubbers. They are commonly used in the following applications:

The HMHT Organic Peroxide Initiators offer several advantages, including:

The HMHT Organic Peroxide Initiators are a high-quality product that offers efficient and reliable initiation for various polymerization processes. With its high purity, excellent stability, and low toxicity, it is a preferred choice for many industries. With a trusted brand name and model number, HMHT0087, these initiators are a valuable addition to any production process.

Organic peroxide initiators are packaged in specialized containers to ensure their stability and safety during transportation and storage. The packaging materials used are selected based on their compatibility with the specific type of organic peroxide initiator. The containers are also properly labeled with necessary information such as product name, batch number, date of manufacture, and handling instructions.

Organic peroxide initiators are typically packaged in high-density polyethylene (HDPE) containers, which are known for their chemical resistance and durability. These containers are available in various sizes to suit different quantities of the initiator. For smaller quantities, glass or plastic bottles may also be used.

Organic peroxide initiators are classified as hazardous materials and are subject to strict regulations for shipping. They must be transported in compliance with international and national regulations for the safe handling and transportation of hazardous materials. Proper packaging, labeling, and documentation are required for transportation by air, sea, or land.

The containers are carefully packed in appropriate protective materials to prevent any damage or leakage during transit. They are also marked with appropriate hazard labels and symbols to alert handlers of the potential risks. Additionally, the necessary documentation, such as safety data sheets, shipping manifests, and permits, must accompany the shipment.

Organic peroxide initiators must be stored in a cool, dry, and well-ventilated area, away from direct sunlight and sources of heat. They should be kept in their original, tightly closed containers to prevent exposure to air and moisture. Proper storage conditions are essential for maintaining the stability and effectiveness of the initiators.

It is recommended to keep the initiators separated from other chemicals and materials to avoid potential reactions. They should also be stored in a designated area with restricted access to authorized personnel only.

Overall, proper packaging and shipping are crucial for ensuring the quality and safety of organic peroxide initiators. Any damaged or expired containers should be disposed of according to local regulations and guidelines.